SERVİCES

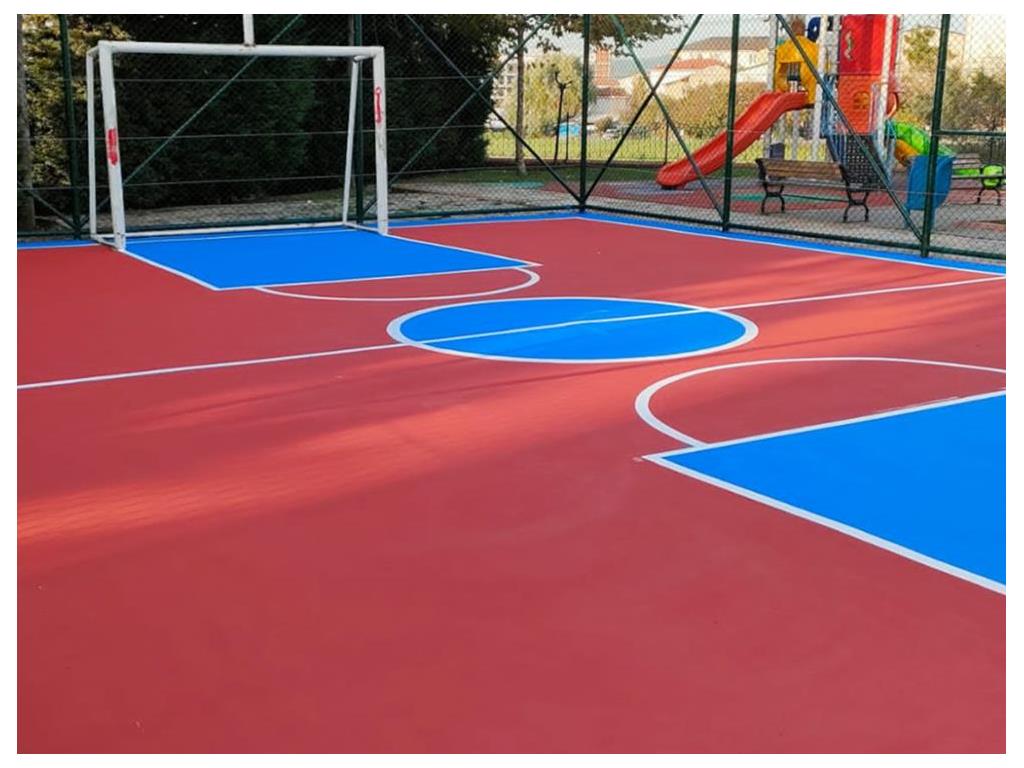

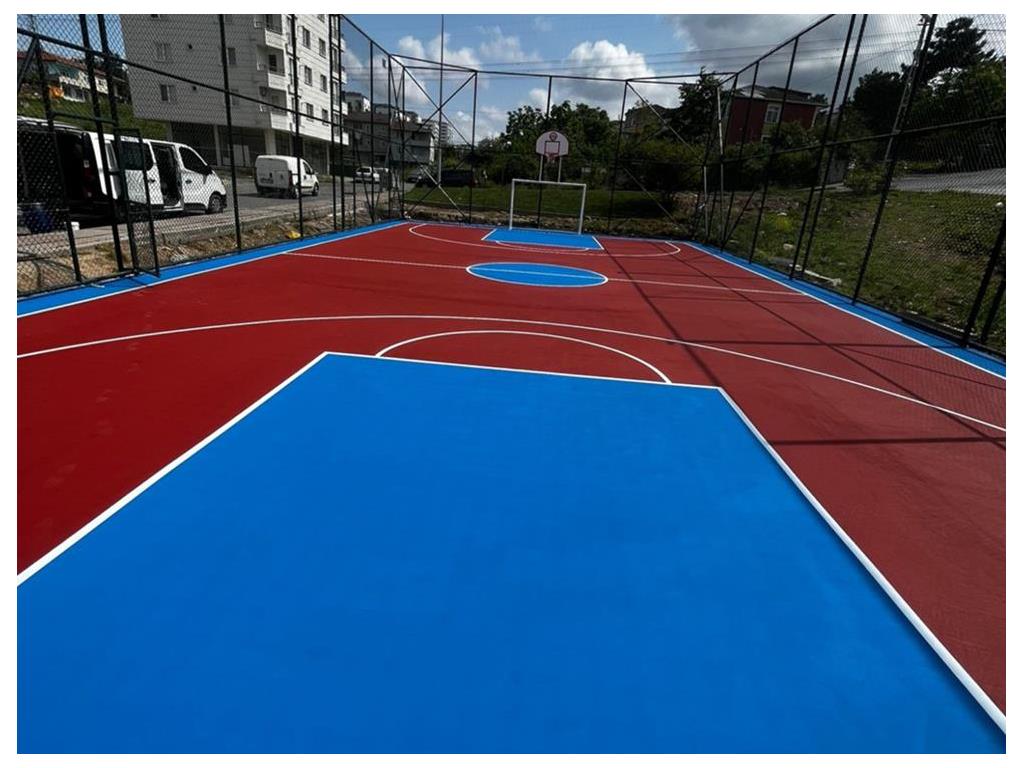

BASKETBALL COURT CONSTRUCTION

• Ground leveling is carried out.

• After ground improvement and compaction, excavation work is done for laying the field's wooden/steel molds.

• Reinforcement/steel bars are placed, and connections are completed in the area designated for the slab concrete.

• C20-C25 concrete is poured into the molds created for the slab.

• 20 cm of grade 3 gravel is spread into the pool and compacted with a roller, with a slope of 0.007% during the process.

• On this layer, 10 cm of mechanical stabilization is spread and compacted with a roller.

• Upon completion of compaction, Q131 x Q131 steel mesh is laid as a single layer on the stabilized surface.

• Ready for concrete pouring, 10 cm of C20-C25 concrete is poured onto the prepared ground, and helicopter finishing is performed.

• This prepares the ground for ironwork.

• Once ready for ironwork, the flanges of the basketball court are placed at equal intervals, with a spacing of 3.00m.

• Main posts are erected on the placed flanges, crossbars are laid, and welding is completed.

• After laying the crossbars, the mesh wire is not pulled, as asphalt coating will be applied in subsequent stages.

• Connections are made for 400w or 140w LED projectors according to the conditions specified in the basketball court project.

• It is laid using a 5cm zero asphalt finisher, and manual laying can also be done if preferred.

• During asphalt laying, leveling is carried out, which prevents the formation of puddles on the court.

• The tension wires of the ready-made iron structure are pulled.

• Then, 50x50x3.50mm PVC-coated mesh wires undergo tensioning processes and connections are made.

• The assembly of the basketball hoop is carried out.

• Placed in a 114.00mm drilled hole using a core drill, the hoop is positioned without leaving any gaps, and the connection to the backboard is made.

• Optionally, a wheeled portable basketball hoop can be constructed.

• After asphalt is laid, there is a waiting period of 10-15 days.

• During this time, it is recommended to water the ground daily to release gases from the court.

• If done before this waiting period, cracks may occur in the flooring.

• After releasing the asphalt gases, the acrylic coating process is initiated.